Lower emissions - higher returns

GasAbate by GlasPort Bio is a breakthrough, globally patented biotech solution that cuts methane emissions from stored manure by 80%, boosts slurry nutrient retention and improves animal welfare through better air quality

Real-time emissions data

Our world-class Compli360 measurement, reporting and verification (MRV) system provides end-to-end remote monitoring and cloud-based emissions data to enable companies to account for methane emissions reductions

Government submission

The Climate Change Advisory Council is calling on Government to increase the pace of emissions reductions, with the roll-out of methane-reducing manure additives their No1 recommendation. We made the same point in our submission

STORED SLURRY

The GasAbate effect

% less methane

% less hydrogen sulphide

% less ammonia

✓ Reduces hydrogen sulphide by 80%

✓ Reduces odours & improves air quality

✓ Improves slurry nutrient retention

✓ Fully automated operation & reporting

MEASUREMENT, REPORTING & VERIFICATION

Real-time emissions data

GasAbate installation causes no disruption to farming operations and can be installed with animals indoors

Our built-in data-gathering system gives live information on slurry levels, additive usage and saved emissions

Additive levels are monitored remotely by GlasPort Bio with new deliveries ordered automatically if running low

Automated reporting at individual farm and group level gives full insight into the performance of the system

BEYOND EMISSIONS

Tangible farm-level benefits

Enhanced nutrient retention

GasAbate reduces nitrogen and sulphur losses during storage, preserving the nutrient value of slurry. Research presented by Queen’s University Belfast shows that GasAbate-treated pig slurry increased plant growth by 20% compared to untreated stored slurry. This is attributed to reduced ammonification and lower hydrogen sulphide emissions.

Improved air quality and animal welfare

In swine housing systems, reduced emissions of ammonia and hydrogen sulphide lead to significantly improved air quality. This has been linked to better animal performance, reduced respiratory stress and enhanced welfare standards. The reduction in odour also improves working conditions and reduces nuisance for surrounding communities.

Reduced slurry separation and agitation

GasAbate-treated slurry separates less, reducing the need for mechanical agitation before spreading. This saves time and fuel while lowering the risk of exposure to toxic gases such as hydrogen sulphide - a major health and safety concern on farms worldwide.

Anaerobic digestion compatibility

GasAbate preserves the energy content of slurry, making it an ideal feedstock for anaerobic digestion. Trials show that the biomethane yield of GasAbate-treated slurry is comparable to that of fresh slurry, supporting renewable energy production without compromising efficiency.

Phosphorus management

In regions with phosphorus-sensitive catchments, GasAbate helps retain more phosphorus in the solid fraction of slurry. This reduces the risk of nutrient run-off into watercourses, supporting compliance with environmental regulations and improving soil fertility management.

COST SAVINGS

Economic benefits

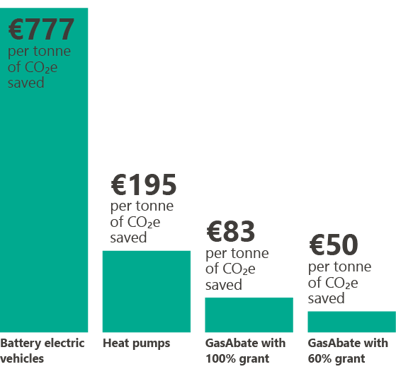

The cost to Ireland per tonne of CO₂e saved with GasAbate is estimated at €83 for a 100% grant and €50 for a 60% grant – substantially less than the levels currently applying to heat pumps at €195/t and battery electric vehicles estimated at €777/t.

But this is not just an Irish problem; GasAbate is globally patented and can by used by any company or country to lower greenhouse gas emissions from agriculture.

TESTIMONIALS

Everyone stands to gain [from GasAbate] ... It's non-invasive, it's non-disruptive, it doesn't require farmers to change anything that they do, it's scalable and it can be done almost overnight.

George Lee, RTÉ Environment Correspondent

Installing GasAbate, the running of it doesn’t affect my farming operations in any way. The benefit to me is reduced agitation time, reduced foaming, reduced odour and hopefully increased nutrients in the slurry.

Raymond Goggin, dairy farmer, Cork

The agitation time of GasAbate-treated slurry was halved – less labour and cost to me. The smell of hydrogen sulphide in the sheds was significantly reduced.

Ken McGrath, pig farmer & owner of Ashleigh Farms, Waterford

There's less smell and less labour time needed to agitate slurry after GasAbate treatment of my stored slurry. I would estimate about 50% less labour needed for agitation of treated slurry.

John Finn, dairy farmer, Galway

OUR PARTNERS

If you work for a company or co-op and would like to partner with us, please click here. If you're an individual farmer and would like more details, please click here.